Proper attic and wall insulation is crucial for energy efficiency and comfort in any home. This comprehensive guide explores the essential steps to effectively insulate your home, from selecting the right materials to troubleshooting common issues. We’ll delve into various insulation types, installation methods, and crucial considerations for achieving optimal results.

Understanding the different insulation materials, their respective R-values, and installation techniques will help you make informed decisions. We will also provide a detailed comparison of various methods, along with their costs and benefits. This knowledge will empower you to choose the most suitable approach for your specific needs and budget.

Introduction to Attic and Wall Insulation

Proper insulation of attics and walls is crucial for maximizing energy efficiency and comfort in any building. Insulation acts as a barrier, preventing heat transfer between the interior and exterior environments. This significantly reduces energy consumption for heating and cooling, resulting in lower utility bills and a smaller carbon footprint. The right insulation choice depends on various factors, including the building’s climate, budget, and desired level of comfort.Effective insulation reduces energy loss through walls and attics, leading to lower energy bills and a reduced environmental impact.

This reduction in energy consumption also contributes to a more sustainable lifestyle, helping to mitigate climate change. Understanding the different types of insulation and their characteristics is essential for making informed decisions about improving a building’s thermal performance.

Types of Insulation Materials

Various insulation materials are available, each with its own set of properties and applications. Understanding these differences is key to selecting the most suitable material for a specific situation. Common types include fiberglass, cellulose, spray foam, and mineral wool. Each offers unique advantages and disadvantages in terms of cost, installation, and performance.

Comparison of Insulation Types

This table provides a concise comparison of common insulation materials, considering cost, installation complexity, and thermal performance. Careful consideration of these factors is vital for selecting the most appropriate insulation for a given project.

| Material | Cost | Installation Difficulty | R-Value | Pros | Cons |

|---|---|---|---|---|---|

| Fiberglass | Moderate | Relatively easy | Good | Affordable, readily available, good thermal performance | Can be dusty during installation, potential for moisture absorption if not properly sealed |

| Cellulose | Moderate | Relatively easy | Good | Environmentally friendly, cost-effective, excellent fire resistance | Can be more difficult to work with in tight spaces, potential for settling over time |

| Spray Foam | High | More complex | Excellent | High R-value, excellent air sealing, long-term durability | Higher upfront cost, specialized installation required, potential for off-gassing |

| Mineral Wool | Moderate to High | Relatively easy | Good | Excellent fire resistance, good thermal performance, relatively durable | Can be heavier than other options, potentially higher installation costs depending on type |

Benefits of Proper Insulation

Proper insulation significantly contributes to reducing energy costs and minimizing environmental impact. By effectively sealing air leaks and minimizing heat transfer, insulation leads to more consistent indoor temperatures, lowering the need for energy-intensive heating and cooling systems. This direct impact translates to reduced carbon emissions, a crucial aspect of environmentally responsible building practices.

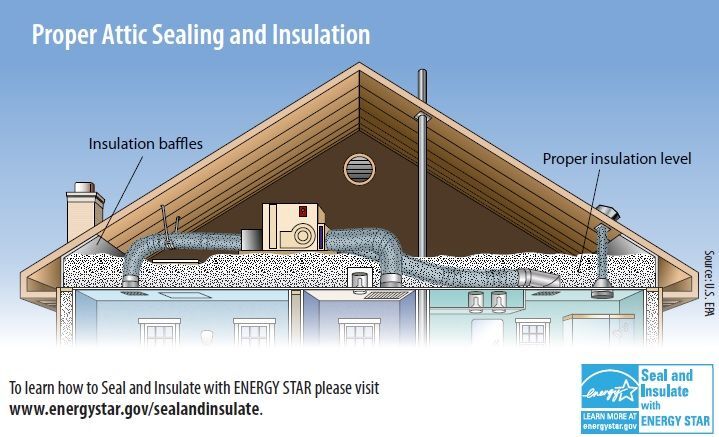

Attic Insulation Methods

Proper attic insulation is crucial for maintaining a comfortable indoor temperature and reducing energy consumption. Effective insulation significantly minimizes heat transfer between the attic and the living space, leading to lower utility bills and a more sustainable home. This section will detail various insulation methods, their installation procedures, and important considerations for optimal performance.Effective attic insulation involves careful selection of the appropriate insulation type and method, considering factors such as the attic’s structure, existing materials, and desired level of insulation.

Understanding these choices allows for a well-informed decision, leading to an efficient and cost-effective insulation solution.

Choosing the Right Insulation Type

Different insulation types have varying characteristics, affecting their effectiveness and suitability for different attics. Consider the R-value, or thermal resistance, of the material. A higher R-value indicates better insulation properties. Also, take into account factors such as fire resistance, moisture resistance, and ease of installation. Different insulation types provide varying degrees of these properties.

Attic Insulation Installation Techniques

Various methods are available for installing attic insulation, each with its own advantages and disadvantages. The choice depends on the specific needs of the attic and the installer’s expertise.

- Blown-in insulation: This method involves using specialized equipment to blow insulation fibers into the attic’s void spaces. It’s particularly useful for filling irregular shapes and hard-to-reach areas. This method is efficient for complex or challenging attic configurations. It’s often a time-saving approach, especially when dealing with large areas.

- Batt insulation: Pre-cut insulation boards are installed in the attic’s framing. Batt insulation is a widely used and relatively straightforward method. It provides good thermal performance and is suitable for many standard attic configurations. Proper installation is key to ensuring adequate insulation and avoiding gaps.

- Spray foam insulation: A specialized material is sprayed into the attic’s void spaces, creating a continuous layer. This method offers excellent air sealing and insulation properties, often leading to enhanced energy efficiency. However, it can be more expensive than other methods and requires specialized equipment and expertise.

Step-by-Step Batt Insulation Installation

Installing batt insulation involves several key steps for a successful outcome.

- Preparation: Carefully assess the attic’s structure and identify any potential obstacles. Ensure the area is clear of obstructions and adequately ventilated.

- Measuring: Accurately measure the area to be insulated to determine the correct amount of insulation needed. This prevents unnecessary waste and ensures adequate coverage.

- Insulation Placement: Carefully position the batt insulation between the attic’s framing members. Ensure proper alignment to prevent gaps and air leakage. Stagger the seams to minimize potential weak points.

- Finishing: Check for any remaining gaps or areas requiring additional insulation. This step is vital for maintaining a consistent level of insulation and preventing thermal bridging.

Common Attic Insulation Mistakes and How to Avoid Them

| Mistake | Explanation | Solution |

|---|---|---|

| Insufficient insulation depth | Not using enough insulation to achieve the desired R-value. | Use the recommended insulation depth based on local building codes and desired energy efficiency. |

| Improper ventilation | Poor ventilation can lead to moisture buildup, potentially damaging the insulation. | Ensure proper ventilation throughout the attic to prevent moisture problems and maintain a healthy environment. |

| Incorrect insulation type | Using the wrong type of insulation for the attic’s conditions. | Choose the appropriate insulation type based on factors such as moisture resistance, fire resistance, and the attic’s structural characteristics. |

| Inadequate sealing | Leaving gaps or holes in the insulation that allow air to leak. | Seal any gaps or holes with appropriate materials, such as caulk or spray foam, to prevent air leaks. |

Importance of Attic Ventilation

Proper ventilation in attics is essential for maintaining a healthy environment. It prevents moisture buildup, which can damage the insulation and the structure itself. Adequate ventilation is essential for the longevity and effectiveness of the insulation.

Types of Attic Access Points and Their Implications

The type of attic access point affects the insulation installation process. Knowing the type of access is critical for planning and executing the insulation project.

- Roof hatches: These provide easy access for insulation installation. The size and placement of the hatch can affect the insulation process. Careful planning and consideration of the hatch size and location are crucial to ensure effective insulation.

- Pull-down stairs: Access through these stairs often requires specific insulation techniques. The limited space and the way the stairs are designed may affect the types of insulation and methods that can be used.

Wall Insulation Methods

Proper wall insulation is crucial for energy efficiency and comfort in a building. Different techniques address various aspects of the wall structure, from cavities to exterior surfaces, offering diverse solutions for optimal thermal performance. Careful consideration of these methods is vital for minimizing heat loss and maximizing indoor temperature control.

Comparison of Wall Insulation Techniques

Various wall insulation techniques cater to different building types and needs. Cavity insulation, a common approach, fills the air space between wall studs, reducing heat transfer. Exterior insulation, on the other hand, adds an insulating layer to the exterior wall surface, providing enhanced thermal resistance and improving the overall building envelope. Exterior insulation offers a significant advantage in terms of improving the building’s energy efficiency and often allows for better air sealing, reducing drafts.

Rigid Foam Board Insulation Installation

Rigid foam board insulation is a popular choice for its effectiveness and ease of installation. It provides excellent thermal resistance and is relatively straightforward to work with.

- Preparation: Ensure the wall studs are properly aligned and spaced. Remove any existing insulation or debris from the cavity. Measure and cut the foam board insulation to the exact dimensions of the cavity, ensuring precise fit. Prepare the cavity by sealing any gaps or openings with appropriate caulk.

- Installation: Carefully place the foam board insulation pieces between the studs, ensuring a snug fit. Avoid any gaps or air pockets that could compromise insulation effectiveness. Use appropriate fasteners, such as construction adhesive, to secure the foam board to the studs.

- Finishing: Once all the foam board insulation is installed, the cavity should be thoroughly sealed. Apply a vapor barrier to prevent moisture from entering the insulation and compromising its performance.

Exterior Wall Insulation Installation

Exterior wall insulation significantly enhances a building’s thermal performance. This method often requires specialized techniques and materials.

- Preparation: Carefully inspect the existing wall structure, identifying any necessary repairs or modifications. Determine the appropriate insulation material and system based on the building’s design and climate conditions. Ensure the chosen insulation system meets local building codes and guidelines.

- Installation: Install the exterior insulation system, ensuring proper adherence to the wall surface. Follow the manufacturer’s instructions carefully to maintain the integrity of the system. This may involve attaching the insulation boards directly to the exterior wall or using a specialized cladding system.

- Finishing: Complete the installation by sealing any gaps or openings to prevent air infiltration and moisture ingress. Ensure proper ventilation and drainage around the insulation system to maintain its longevity and performance.

Types of Exterior Wall Insulation Systems

Various exterior wall insulation systems are available, each with its unique characteristics and benefits. Common options include:

- Insulated sheathing systems: These systems use rigid foam sheathing boards installed directly on the exterior wall, providing superior thermal performance.

- Insulated cladding systems: These systems combine insulation with exterior cladding materials like fiber cement or vinyl siding, creating a finished aesthetic.

- Spray foam insulation: Spray foam insulation is a versatile option that fills all gaps and crevices, ensuring complete coverage and minimizing air leakage.

Importance of Vapor Barriers in Wall Insulation

A vapor barrier is a crucial component in wall insulation. It prevents moisture from entering the insulation and condensing, which can lead to mold growth, structural damage, and decreased insulation performance. Properly installed vapor barriers significantly contribute to the long-term effectiveness and durability of wall insulation.

Addressing Wall Cavities for Proper Insulation

Wall cavities, the spaces between studs, must be properly addressed for effective insulation. Careful attention to these cavities, including proper sealing and insulation placement, ensures optimal thermal performance.

Wall Insulation Methods Cost Comparison

The cost of wall insulation varies significantly depending on the chosen method, materials, and labor costs.

| Insulation Method | Estimated Cost (per square foot) | Advantages | Disadvantages |

|---|---|---|---|

| Cavity Insulation | $1-$3 | Relatively inexpensive, straightforward installation | May not provide the highest R-value |

| Exterior Insulation | $3-$5 | Enhanced energy efficiency, improved building envelope | More complex installation, potential for increased project costs |

| Rigid Foam Board Insulation | $2-$4 | Good thermal performance, relatively easy installation | May require additional labor for cutting and fitting |

Note: Costs are estimates and can vary based on location, material choices, and labor rates.

Insulation Materials and Selection

Choosing the right insulation material is crucial for achieving optimal energy efficiency and comfort in a building. Different insulation types offer varying levels of thermal performance, environmental impact, and installation costs. Understanding these factors allows homeowners and builders to make informed decisions that align with their specific needs and values.Insulation materials are selected based on their ability to resist heat transfer.

This property, quantified by the R-value, directly impacts the overall thermal performance of the building. A higher R-value signifies greater resistance to heat flow, leading to lower energy consumption and reduced heating and cooling costs. Considerations also extend to the material’s installation characteristics, cost, and environmental impact.

R-Value Comparison of Insulation Materials

Different insulation materials possess varying R-values, reflecting their capacity to impede heat transfer. Understanding these differences is essential for selecting the appropriate insulation for a specific building type and climate. Factors like the material’s density, thickness, and composition directly influence its R-value.

- Fiberglass Insulation: Fiberglass insulation is a widely used, cost-effective option. It’s available in batts, rolls, and loose-fill forms, making it adaptable to various installation scenarios. Its relatively low R-value compared to other materials necessitates thicker installations for equivalent performance. Fiberglass is typically considered a moderate performer in terms of thermal resistance. Its cost-effectiveness makes it a suitable choice for budget-conscious projects.

- Mineral Wool Insulation: Mineral wool, often made from rock or slag, provides good thermal resistance and fire resistance. Its R-value is generally comparable to fiberglass, but its higher density often leads to slightly superior performance. The durability and fire resistance make it an appealing choice for high-risk applications or areas requiring extended lifespan.

- Cellulose Insulation: Cellulose insulation is a recycled material derived from paper products. It offers good thermal resistance and excellent sound absorption. Its R-value is comparable to fiberglass and mineral wool, but its excellent air sealing properties contribute to enhanced overall performance. Its environmentally friendly nature makes it a popular choice for environmentally conscious builders.

- Spray Foam Insulation: Spray foam insulation, available in closed-cell and open-cell varieties, is known for its exceptional air sealing capabilities and high R-value. Its application method can be more complex than other options, but its high performance makes it a superior choice for areas requiring maximum energy efficiency. The high cost of installation is often offset by the long-term energy savings.

Determining the Appropriate R-Value

The appropriate R-value for a building depends on the climate zone and the type of construction. A higher R-value is needed in colder climates to effectively resist heat loss. Consideration of factors like roof slope, wall construction, and window placement are essential. The building’s structural characteristics, along with the desired energy efficiency goals, play a critical role in determining the appropriate insulation level.

- Climate Zone: The climate where the building is located significantly influences the required R-value. Colder climates necessitate higher R-values to maintain comfortable indoor temperatures. Regional building codes often specify minimum R-value requirements based on climate conditions.

- Building Type: Different building types, like residential homes or commercial structures, have varying thermal demands. Factors such as the building’s age, materials, and existing insulation contribute to the determination of the optimal R-value.

Environmental Impact of Insulation Materials

The environmental impact of insulation materials varies considerably. Consideration of the material’s sourcing, manufacturing process, and potential for recycling is critical. Sustainable choices reduce the overall carbon footprint of construction projects.

- Recycled Content: Insulation materials made with recycled content contribute to reduced waste and a more sustainable construction process. The use of recycled materials is increasingly recognized as a critical component of environmentally conscious building practices.

- Manufacturing Processes: The manufacturing process of insulation materials can affect their environmental impact. Eco-friendly manufacturing methods minimize pollution and promote responsible resource management. Energy efficiency in the manufacturing process is an important factor to consider.

- End-of-Life Considerations: The end-of-life considerations for insulation materials include potential for recycling and disposal methods. Materials that can be easily recycled or repurposed have a lower environmental footprint.

Safety Precautions and Handling

Proper handling and safety precautions are essential when installing insulation materials. Some materials can pose health risks if not handled correctly. Adherence to safety guidelines is crucial for both installers and homeowners.

- Dust Control: Certain insulation types, such as fiberglass, generate dust during installation. Dust control measures, including proper ventilation and the use of respirators, are essential for worker and homeowner safety.

- Material Specific Instructions: Each insulation material has specific handling and safety instructions. Carefully review the manufacturer’s instructions before installation to ensure compliance with safety regulations.

- Proper Ventilation: Adequate ventilation during installation is crucial to minimize exposure to airborne particles and ensure a healthy working environment.

Insulation Material Comparison Table

| Insulation Material | Typical R-Value (per inch) | Typical Installation Cost (per sq ft) |

|---|---|---|

| Fiberglass | 3.0-4.0 | $0.50-$1.50 |

| Mineral Wool | 3.5-4.5 | $0.75-$1.75 |

| Cellulose | 3.5-4.5 | $0.70-$1.50 |

| Spray Foam | 4.0-6.0 | $2.00-$4.00 |

Note: Installation costs are approximate and can vary based on location, labor rates, and specific project requirements.

Inspection and Maintenance

Regular inspection and maintenance are crucial for ensuring the longevity and effectiveness of your insulation. Properly maintained insulation systems will not only improve energy efficiency but also reduce potential issues and maintenance costs in the long run. This proactive approach will help you identify problems early and address them before they escalate into larger, more costly repairs.

Importance of Regular Insulation Inspections

Regular inspections are essential for identifying potential issues early on, preventing costly repairs and maintaining optimal energy efficiency. Addressing minor problems promptly can significantly reduce energy bills and the need for major insulation replacements. A proactive approach to insulation maintenance ensures a comfortable indoor environment throughout the year.

Steps Involved in Inspecting Attic and Wall Insulation

Thorough inspection involves a systematic approach. Begin by visually assessing the insulation layers in the attic and walls. Look for gaps, tears, or areas of inadequate coverage. For attic insulation, check for proper installation and the presence of any air leaks around pipes, vents, or structural elements. When inspecting wall insulation, carefully examine the insulation behind the drywall or sheathing for any gaps or compression.

Use a flashlight to check hidden areas and inspect the insulation’s overall condition.

Signs of Inadequate Insulation

Several signs indicate inadequate insulation. High energy bills, uneven temperatures within the home, condensation on windows or walls, and drafts are common indicators of inefficient insulation. Unusual moisture buildup in specific areas may also point to air leaks or inadequate insulation. These signs can be indicators of problems that should be addressed promptly.

Common Insulation Maintenance Tasks

Regular maintenance tasks help preserve the insulation’s effectiveness. These include sealing air leaks around windows and doors, inspecting and sealing any cracks or gaps in the attic or walls, and checking the insulation levels for proper density. Cleaning the attic to remove debris and dust can also contribute to insulation efficiency. Ensuring that insulation remains in place and free from compression is vital.

Best Practices for Maintaining Insulation Efficiency

Maintaining insulation efficiency involves several best practices. Regularly inspect insulation for damage or deterioration, sealing any gaps or openings promptly. Proper ventilation and moisture control are crucial. Keep the insulation dry and free from moisture buildup, and ensure that insulation materials are properly installed. Regular inspections and preventative measures will minimize the need for major repairs or replacements.

Identifying and Addressing Insulation Problems

Addressing insulation problems, such as air leaks, requires a methodical approach. Locate air leaks by using a smoke stick or similar devices to identify areas where air is seeping. Seal these leaks with appropriate materials, such as caulk or weatherstripping. If you notice inadequate insulation levels, consult with a qualified professional to determine the best course of action for a more comprehensive solution.

Understanding the location and nature of the problem is critical for effective repair and maintenance.

Energy Efficiency Considerations

Proper insulation significantly enhances a building’s energy efficiency, reducing reliance on heating and cooling systems. This translates to lower energy bills and a smaller carbon footprint. Effective insulation minimizes heat transfer, maintaining desired indoor temperatures with less energy expenditure.Insulation’s impact extends beyond initial savings. It contributes to long-term cost reductions and often improves indoor air quality, creating a healthier living environment.

By understanding the interplay between insulation, energy efficiency, and indoor air quality, homeowners can make informed decisions about their building’s insulation needs.

Impact on Heating and Cooling Costs

Proper insulation significantly reduces the amount of energy needed to heat and cool a building. By reducing heat loss in winter and heat gain in summer, insulation minimizes the work required of the HVAC system. This directly translates to lower utility bills. For example, a well-insulated home can experience heating costs reduced by 20-30% compared to a poorly insulated one in similar climates.

Similarly, cooling costs can be lowered by 15-25%.

Comparison with Other Energy-Saving Strategies

Insulation stands as a highly effective energy-saving strategy. While other measures like energy-efficient appliances or sealing air leaks are beneficial, insulation’s consistent and long-term impact on thermal performance makes it a cornerstone of energy efficiency. For instance, replacing incandescent light bulbs with LEDs saves energy, but insulation tackles the larger issue of uncontrolled heat transfer. Sealing air leaks reduces drafts, but insulation provides a consistent barrier to heat flow throughout the entire building envelope.

Long-Term Savings

The long-term savings associated with proper insulation are substantial. Lower energy bills translate to substantial cost savings over the lifespan of the building. Furthermore, the reduced wear and tear on heating and cooling systems prolongs their lifespan, minimizing future repair and replacement costs. A well-insulated home can save thousands of dollars in energy costs over its lifetime, making insulation a sound investment.

Relationship between Insulation and Indoor Air Quality

Insulation plays a vital role in maintaining a healthy indoor environment. By reducing drafts and preventing the infiltration of outside air, insulation helps regulate indoor temperature and humidity, contributing to a more stable and comfortable environment. This stability reduces the potential for mold and mildew growth, enhancing indoor air quality. Furthermore, a well-insulated home is less prone to fluctuating temperatures, which can be detrimental to the health of some occupants.

Energy Efficiency Gains with Different Insulation Types

| Insulation Type | Estimated Energy Efficiency Gain (Compared to Standard Insulation) | Comments |

|---|---|---|

| Fiberglass Batt | 15-25% | Common, affordable, good for walls and attics. |

| Cellulose | 20-30% | Environmentally friendly, good for attics and walls, often higher cost. |

| Spray Foam | 25-40% | Excellent for sealing gaps, good for walls and attics, high cost. |

| Mineral Wool | 20-30% | Fire resistant, good for attics and walls, more expensive than fiberglass. |

| Rigid Foam | 25-40% | Good for exterior walls, excellent for sealing, high cost. |

Note: Energy efficiency gains are estimations and can vary based on the specific building, climate, and installation quality.

Troubleshooting Common Insulation Issues

Proper insulation installation is crucial for energy efficiency and comfort in a home. However, problems can arise over time, affecting the effectiveness of the insulation. Addressing these issues promptly is essential to maintain the intended benefits of insulation. This section will detail common insulation problems, their causes, identification, repair methods, and preventive measures.

Common Insulation Problems and Their Causes

Insulation problems can stem from a variety of factors, including material defects, installation errors, and environmental impacts. Understanding the root causes is key to effective troubleshooting. Poor quality insulation materials, improper installation techniques, or inadequate sealing can lead to significant issues over time. Additionally, moisture, pests, or structural changes can also impact the effectiveness of insulation.

Identifying Insulation Material Issues

Visual inspection is often the first step in identifying insulation problems. Look for signs of damage, such as cracks, holes, or missing sections. Compaction or excessive settling can indicate inadequate insulation thickness. Moisture damage, often characterized by mold or mildew growth, significantly reduces the insulating properties of the material. Inspect the insulation for evidence of pest infestation, such as gnawed areas or droppings.

Addressing Damaged or Deteriorated Insulation

Repairing damaged insulation depends on the extent of the damage and the type of insulation used. Minor tears or holes in loose-fill insulation can often be patched with more of the same material. For fiberglass batts, replacing the damaged section with a new batt is usually the most effective approach. If moisture is a factor, addressing the underlying source is crucial.

This might involve waterproofing the affected area or improving ventilation. For significant damage, it may be necessary to remove and replace the entire insulation layer.

Common Insulation Installation Errors

Installation errors are a significant cause of insulation problems. Improperly installed insulation may not meet the required thickness or fill gaps adequately. Poorly sealed seams or gaps can allow air to infiltrate the insulated space, reducing the insulation’s effectiveness. Ensuring proper ventilation around the insulation is essential to prevent moisture buildup. Inaccurate measurements and improper sealing can also compromise the insulation’s efficiency.

Air Leaks Around Insulation

Air leaks around insulation are a common cause of thermal bridging. This occurs when air circulates through gaps and cracks, creating a path for heat transfer. Identifying these leaks requires careful inspection. Look for gaps around windows, doors, and electrical outlets. Check for cracks in the walls or ceilings.

Caulk or seal any identified gaps to minimize air infiltration. Properly sealing the insulation is critical to achieving the intended insulation levels.

Table of Common Insulation Problems and Solutions

| Problem | Cause | Solution |

|---|---|---|

| Compacted Insulation | Improper installation, settling, or movement of the structure | Remove the compacted insulation and replace with the appropriate material, ensuring proper installation. |

| Moisture Damage | Leaks, condensation, or inadequate ventilation | Identify and repair the source of moisture, improve ventilation, and use moisture-resistant materials. |

| Pest Infestation | Presence of rodents or insects | Eliminate the pest infestation and seal any entry points. |

| Air Leaks | Gaps around windows, doors, or other openings | Seal gaps with caulk, weatherstripping, or other appropriate methods. |

| Improper Installation | Inadequate thickness, incorrect material type, or poor sealing | Remove and reinstall the insulation correctly, ensuring the correct thickness and sealing. |

Closing Summary

In conclusion, implementing proper attic and wall insulation is a significant investment in your home’s long-term energy efficiency and comfort. By carefully considering the different materials, installation methods, and energy efficiency considerations, you can achieve significant cost savings and reduce your environmental impact. Regular inspections and maintenance will ensure your insulation remains effective over time. This guide serves as a comprehensive resource to help you achieve optimal insulation performance.